Back to blog

How to Inspect a Used Injection Moulding Machine Before Buying

Apr 16, 2025

Andrea Balajová

Purchasing a used injection moulding machine can be a smart, cost-effective decision for manufacturers looking to expand capacity or reduce capital expenditure. However, to ensure a safe investment, it’s essential to carry out a thorough inspection of the machine before finalizing the purchase.

In this guide, we’ll walk you through the key areas to inspect, what to look out for, and how to evaluate the machine’s condition to avoid surprises after delivery.

1. Start with Documentation and Service History

Before you physically inspect the machine, ask the seller or dealer for the following:

• Complete service records (maintenance intervals, repairs, upgrades)

• Original technical documentation (manuals, wiring diagrams, CE certificates)

• Previous usage details (type of production, operating hours, material used)

A well-documented machine typically indicates that it was maintained properly, and knowing its background helps anticipate potential wear or replacement needs.

2. Visual Condition: First Impressions Matter

Begin with a visual check of the entire machine:

• Are there signs of corrosion, oil leaks, or damaged components?

• Is the paint original or recently reapplied to hide wear?

• Are the tie bars straight and free from scoring?

• Are safety guards and covers intact?

While cosmetic flaws aren’t always critical, they may suggest how the machine was treated during its lifetime.

3. Check the Clamping Unit

The clamping unit undergoes high mechanical stress and must be in good working order.

Inspect the following:

• Tie bars and platens for wear, cracks, or deformation

• Hydraulic cylinders for leaks or inconsistent movement

• Toggle or direct-locking system for smooth operation

• Lubrication points and whether the system works automatically and consistently

Ask to measure the parallelism of the platens — misalignment can damage moulds and affect part quality.

4. Inspect the Injection Unit

This is the heart of the machine, and small issues here can become costly.

Check:

• Screw and barrel for wear (look for signs of abrasion, corrosion, or low compression)

• Nozzle condition and proper heating

• Heaters and thermocouples for consistent temperature control

• Check valve function and seal

• Plasticizing capacity — is it still within acceptable performance range?

If possible, ask to perform a screw recovery or injection cycle and watch for inconsistencies.

5. Evaluate the Hydraulic and Electrical Systems

These systems are complex and should be tested thoroughly.

Hydraulic system:

• Look for fluid leaks, hose wear, and pump noise

• Check pressure settings and response times

• Inspect cooling system and filters

Electrical system:

• Test the control unit (often a brand’s proprietary system like Arburg Selogica or Engel CC300)

• Check for fault messages, sensor feedback, and interface responsiveness

• Ensure all safety interlocks and emergency stop functions are working properly

6. Control System and Software

The PLC control is the brain of the machine. An outdated or failing control system can lead to serious operational issues.

Check for:

• Boot-up times and system responsiveness

• Touchscreen or keypad functionality

• Backup and restore options for machine settings

• Availability of software updates or support from the OEM

Older controls may still be functional but harder to service or source parts for.

7. Run the Machine If Possible

If the machine is still connected, request a test run under real or simulated production conditions.

Watch for:

• Startup sequence and cycle time

• Pressure and temperature consistency

• Alarms, vibrations, or abnormal sounds

• Part quality (if mould and material are available)

A live test gives you the clearest picture of machine health.

8. Ask for a Third-Party or Dealer Inspection

If you’re not experienced in machine assessment, consider hiring an independent technician or request a dealer inspection report. At BASTA Machines, we thoroughly inspect and document every machine before listing it for sale — including photos, videos, and condition reports.

9. Consider Spare Parts and OEM Support

Check:

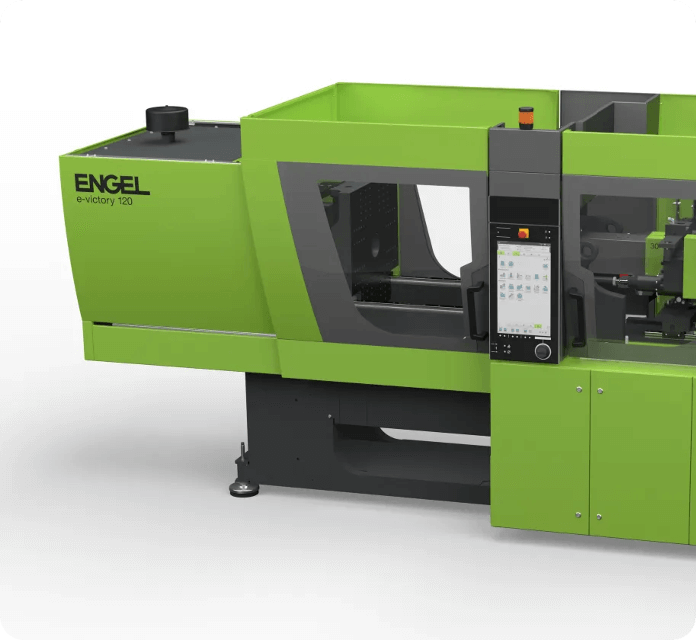

• Is the machine from a major brand (e.g. Arburg, Engel, Demag, Haitian)?

• Are spare parts readily available?

• Is technical support still offered by the manufacturer?

Machines from well-known brands usually offer longer service life thanks to easier sourcing of components.

Final Thoughts

Inspecting a used injection moulding machine doesn’t require advanced tools — just a sharp eye, a checklist, and a bit of knowledge. With a proper inspection, you reduce risk, increase confidence, and get more value from your investment.

Want to see an example inspection?

Check out our helpful videos on YouTube or see our machines working:

Or get in touch with us at www.bastamachines.com — our team is happy to help you choose and inspect the right machine for your needs.

BUY MACHINE