Back to blog

How to Read Injection Moulding Machine Model Numbers: A Beginner’s Guide

Apr 14, 2025

Andrea Balajová

If you’re browsing used injection moulding machines, you’ve probably come across listings with model numbers like ENGEL Victory 330/80 Tech, Arburg Allrounder 470C 1000-290, or Demag Ergotech 500-2000 System. While these combinations of numbers and letters might seem cryptic at first, they actually follow specific naming conventions that provide valuable information about the machine’s capabilities.

In this beginner’s guide, we’ll show you how to decode injection moulding machine model numbers so you can make more informed decisions when buying.

1. Why Model Numbers Matter

Model numbers aren’t random. They typically include data about:

• Clamping force

• Screw diameter

• Machine series or generation

• Optional features or technologies

Understanding what each part of the model number represents helps you quickly identify whether the machine matches your production needs — without diving deep into full technical specs.

2. Breaking Down Common Model Number Formats by Brand

Let’s look at how some of the most popular brands format their model numbers:

Arburg Example: Allrounder 470C 1000-290

• 470C – Refers to the distance between tie bars or size of the clamping unit (470 mm)

• 1000 – The clamping force in kilonewtons → 1000 kN = 100 tons

• 290 – The injection unit size (Arburg’s internal code — usually corresponds to a screw diameter of approx. 30 mm - this affects the shot volume and plasticizing capacity of the machine)

So this machine has a 100-ton clamping force.

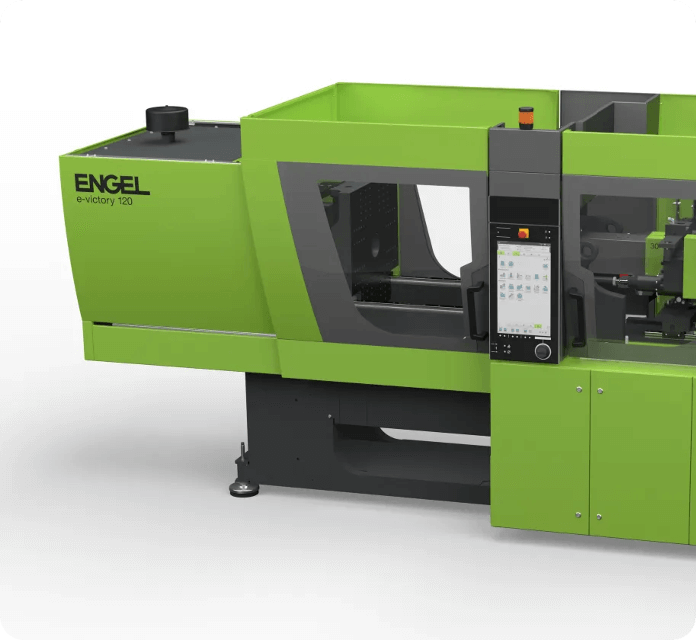

ENGEL Example: Victory 330/80 Tech

• 330 – The screw diameter or shot size (depending on series)

• 80 – The clamping force in tons

• Victory – Refers to the machine series (toggle-free clamping system)

• Tech – Indicates a special version or control system

Note: ENGEL’s naming may vary depending on regional markets and series, but clamping force and shot size are almost always present.

Demag Example: Ergotech 500-2000 System

• 500 – The clamping force in kN → 500 kN = 50 tons

• 2000 – The screw injection pressure unit or size of the injection unit

• System – Indicates control system or configuration

Demag machines are typically labeled with the clamping unit first, then the injection unit.

3. Other Important Abbreviations and Terms

Many brands use additional abbreviations or suffixes that reflect machine features:

• U – Universal or multi-purpose

• T – Tie-barless design

• H – Hydraulic

• E – Electric

• V – Vertical (clamping or injection)

• C – Compact or classic design

• S – Servo-driven

• 2K – Multicomponent

Example: Arburg 420S 800-350 V → Vertical version, 80 tons clamping force, 35 mm screw

4. Why This Matters When Buying Used Machines

Used injection moulding machines are often listed only by model name and year. Knowing how to read the model number helps you:

• Filter out machines that don’t meet your tonnage or size requirements

• Avoid overpaying for a machine that’s too powerful for your product

• Communicate clearly with sellers and brokers

• Choose the right combination of clamping and injection units

At BASTA Machines, we always provide full model names and technical specifications, but understanding how to decode them gives you an edge as a buyer.

5. Need Help Matching the Right Machine?

If you’re unsure how to interpret a specific model or want advice on selecting the right injection moulding machine for your application, our team is here to help. With years of experience in the used machinery market, we can guide you toward the most efficient and cost-effective solution.

Contact us at www.bastamachines.com — and let us help you find the right machine, not just any machine.

BUY MACHINE